Tartana Copper Sulphate Pentahydrate Project

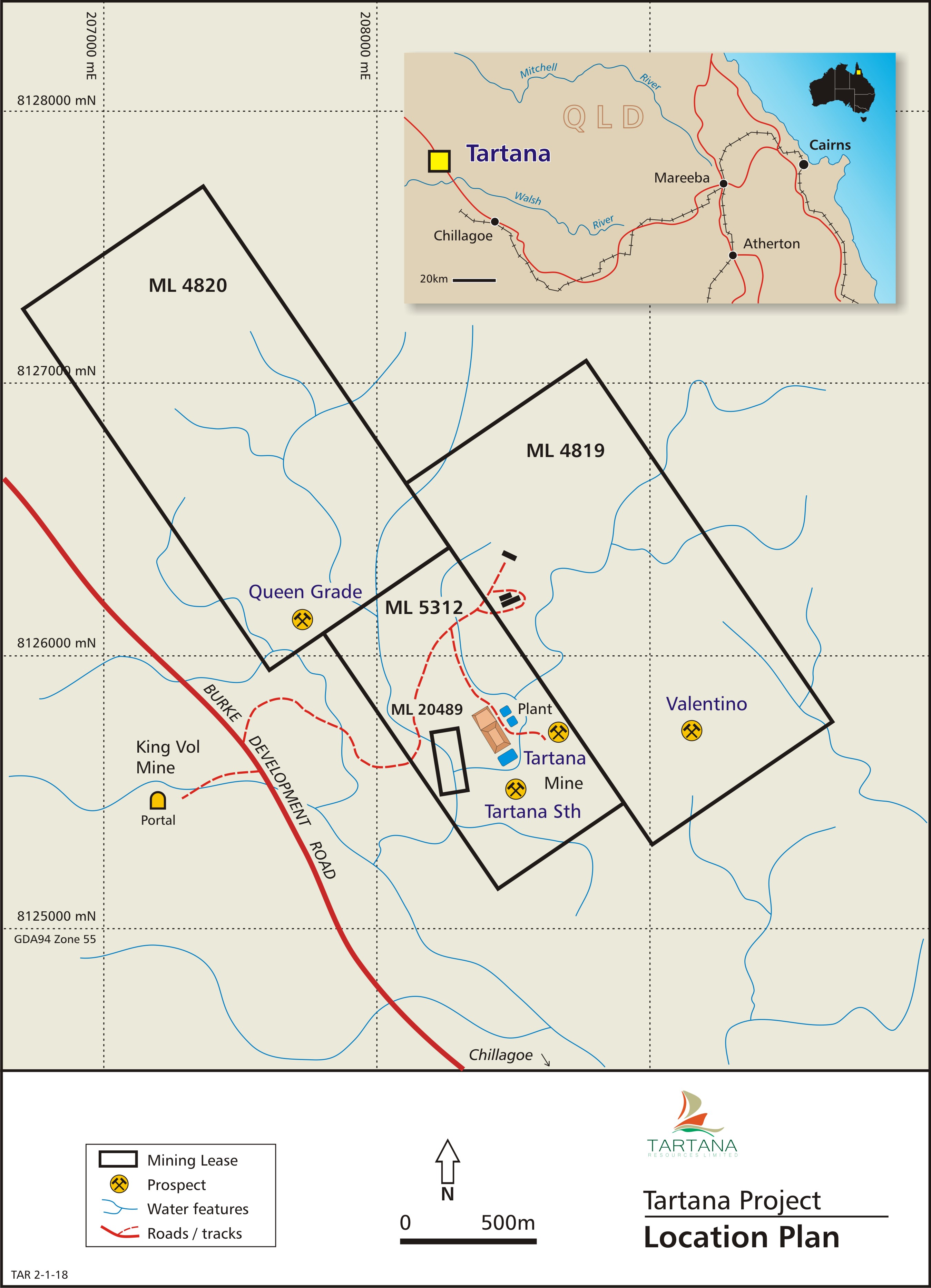

The Tartana Copper Sulphate Project is located on the Tartana mining leases, located approximately 150 km west of Cairns and 40 km northwest of Chillagoe along the Burke Development Road (see below).

The Mining Leases contain a heap leach – solvent extraction – crystallisation plant which produced copper sulphate pentahydrate for approximately a decade before being placed in care and maintenance in 2014. During 2022 the Company has focused on refurbishing the plant for the recommencement of production in early 2023.

Plant refurbishment is well advanced with remaining key items including the electric control panel and wiring and the installation of several new process tanks.

Initial production will commence by sourcing residual copper from the existing heaps and ponds and then other oxide sources on the Tartana leases and elsewhere across the Company’s extensive portfolio of tenements. The plant is complex and historically produced high quality copper sulphate which was utilised in stock feed markets in Australia and southeast Asia as well as supplying technical grade product for northern Australia mining operations. The mining operations use copper sulphate pentahydrate as an activator for sphalerite (zinc sulphide) and pyrite in base metal ore concentrators.

The Company’s business model is likely to involve developing regional oxide copper deposits by establishing on-site small scale leaching operations which produces an intermediate copper product which is then transported back to Tartana where the copper is extracted and upgraded to high-quality copper sulphate pentahydrate attracting a premium.

Copper sulphate Pentahydrate Market

Copper sulphate Pentahydrate is sold to both mining operations and into the stockfeed industry depending on the specifications of the product. The annual demand in Australia is approximately 35,000 tonnes per annum with the northern Australia mini

Copper Sulphate Pentahydrate contains approximately 25% copper with the price based on the LME copper price per tonne (adjusted for the actual copper content i.e., 25%) plus a premium. The premium depends on the quality of the product and the market where the product is being sold.

Plant Flowsheet

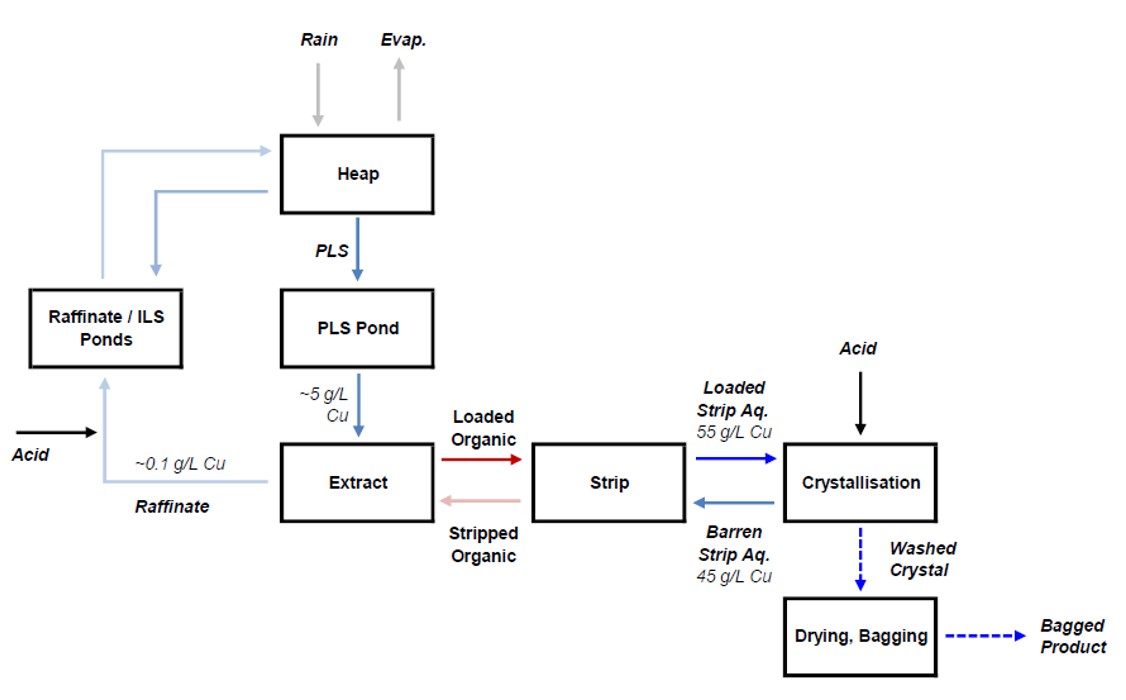

The following diagram depicts the simplified flow sheet. While the process is relatively straightforward, our inhouse expertise is directed towards the ability to purify the liquors and produce a high quality and consistent product.

Sprinklers operating on the lower heap. Note presence of copper (blue).

Sprinklers operating on the lower heap. Note presence of copper (blue).

Plant Refurbishment

Plant refurbishment is well advanced with key items installed or on order. We expect to start commissioning in December 2022 and commence producing saleable product in January 2023. Plant capacity is 9,500 tonnes per annum saleable copper sulphate pentahydrate although historical production rates tended to be between 6,000 – 7,000 tonnes per annum with the lower production rates optimising quality and sale price.

Installation of a new control panel for the generators.

Installation of a new control panel for the generators.

Relaying of the pad and bunding for acid storage.

Installation of the dryer

Process pond sampling